How to Save Money with Expert Commercial Refrigerator Repair Solutions

How to Save Money with Expert Commercial Refrigerator Repair Solutions

Blog Article

Repairing Business Refrigeration Repair Service: Strategies for Quick and Effective Fixes

In the world of business refrigeration, the requirement for swift and exact troubleshooting techniques is extremely important. When a refrigeration unit breakdowns, the consequences can be turbulent and costly to service procedures. Understanding the typical concerns that afflict business refrigeration systems and having a toolkit of diagnostic techniques at hand can make all the distinction in quickly identifying and fixing problems. As we browse through the complexities of troubleshooting commercial refrigeration fixing, we will certainly reveal the key methods for dealing with problems effectively, making sure that services can keep optimal air conditioning performance and decrease downtime.

Typical Business Refrigeration Problems

Industrial refrigeration systems generally run into a range of operational concerns that can interrupt their effectiveness and efficiency. One widespread issue is incorrect temperature level control, which can lead to food spoilage and waste if not immediately dealt with.

Moreover, refrigerant leakages present a considerable concern as they not only impact the air conditioning ability of the system however additionally add to environmental injury. Spotting and fixing leaks quickly is important to avoid additional damages and guarantee compliance with policies. Additionally, filthy condenser coils can impede warmth transfer, forcing the system to function harder and eat even more power. Regular cleansing and upkeep can help prevent this issue and prolong the lifespan of the refrigeration system.

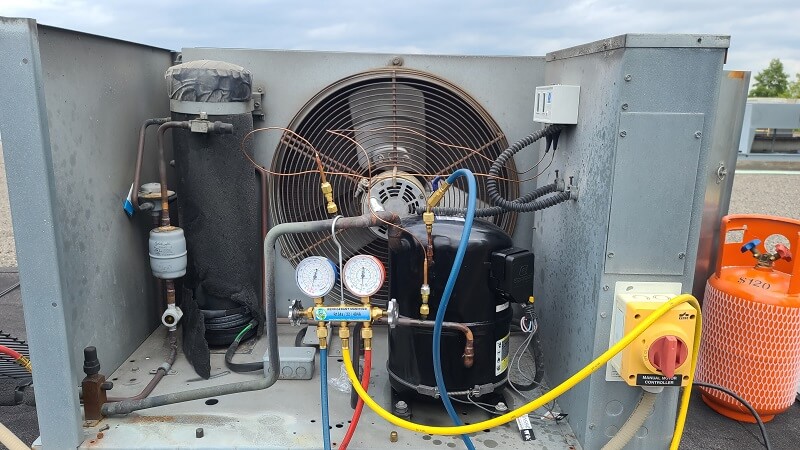

Diagnostic Devices and Techniques

Efficient troubleshooting of industrial refrigeration systems counts heavily on utilizing specialized analysis tools and techniques to identify and settle underlying concerns successfully - commercial refrigeration repair. Furthermore, leakage discovery tools like electronic leakage detectors or ultraviolet dye sets are vital for locating refrigerant leaks that can lead to system inefficiencies.

Information loggers can be used to keep track of system efficiency over time and discover trends that may suggest reoccuring issues. By incorporating these diagnostic tools and techniques, technicians can effectively troubleshoot commercial refrigeration systems and give specific and quick fixings, lessening downtime and making sure optimal system efficiency.

Quick Repairs for Refrigeration Troubles

When encountered with refrigeration issues, service technicians can carry out quick solutions to resolve usual issues swiftly and effectively. One usual fast fix is examining for a dirty condenser coil, which can trigger the system to run inefficiently. Cleaning up the condenser coil consistently can boost the system's efficiency and prevent getting too hot. One more fast fix is ensuring that the refrigerator is not strained, as congestion can restrict airflow and lead to temperature incongruities. Adjusting the shelving to enable appropriate air blood circulation can typically solve this problem. In addition, inspecting the door seals for any indications of wear or damage and replacing them if necessary can assist keep the stability of the seal and prevent air leakages. If the refrigeration system is not cooling properly, inspecting and readjusting the thermostat setups might give a fast option prior to even more thorough troubleshooting is required. By applying these quick repairs, technicians can resolve common refrigeration problems efficiently and maintain commercial refrigeration systems running smoothly.

Preventative Maintenance Tips

Applying an aggressive upkeep timetable is critical for making sure the durability and optimum performance of industrial refrigeration systems. Regular upkeep not only aids prevent pricey malfunctions however also makes sure that the tools operates effectively, saving energy and reducing overall operating costs. Below are some preventative upkeep suggestions to maintain industrial refrigeration systems running smoothly:

Check and Replace Filters: Filthy filters can restrict airflow, making the system job more challenging and possibly triggering damage. Inspect and replace filters consistently to prevent concerns.

Inspect Seals and Gaskets: Leaky commercial refrigerator repair seals and gaskets can bring about temperature level variations and power waste. Inspecting and replacing damaged seals can aid maintain regular temperature levels.

Professional Support and Solutions

To maintain the optimal efficiency achieved with routine preventative upkeep, seeking professional support and services for industrial refrigeration systems is important. Specialist professionals possess the experience and specialized understanding required to detect and resolve complicated issues successfully. When encountering difficult refrigeration problems, relying upon professional support can conserve both money and time in the future.

Professional solutions offer benefits such as accessibility to innovative tools and tools, making certain that repairs are accomplished efficiently. In addition, technicians are educated to comply with sector policies and security criteria, decreasing the danger of mishaps and making sure conformity with lawful requirements.

Verdict

To conclude, fixing industrial refrigeration fixing needs a methodical method to identifying typical problems, using diagnostic devices and strategies, implementing fast fixes, and prioritizing preventative upkeep. Expert support and services might be required for even more facility troubles - commercial refrigerator repair. By following these strategies, companies can guarantee their refrigeration systems operate efficiently and efficiently, minimizing downtime and prospective losses

Comprehending the typical issues that pester business refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the difference in quickly determining and remedying issues.Reliable troubleshooting of commercial refrigeration systems depends heavily on making use of specialized analysis tools and techniques to identify and resolve underlying problems successfully. By integrating these analysis tools and techniques, technicians can properly troubleshoot industrial refrigeration systems and offer quick and accurate repairs, minimizing downtime and ensuring optimal system efficiency.

By executing these quick fixes, technicians can attend to typical refrigeration issues efficiently and keep commercial refrigeration systems running efficiently.

In addition, professional assistance can help expand the life-span of commercial refrigeration systems by recognizing potential problems prior to they intensify.

Report this page